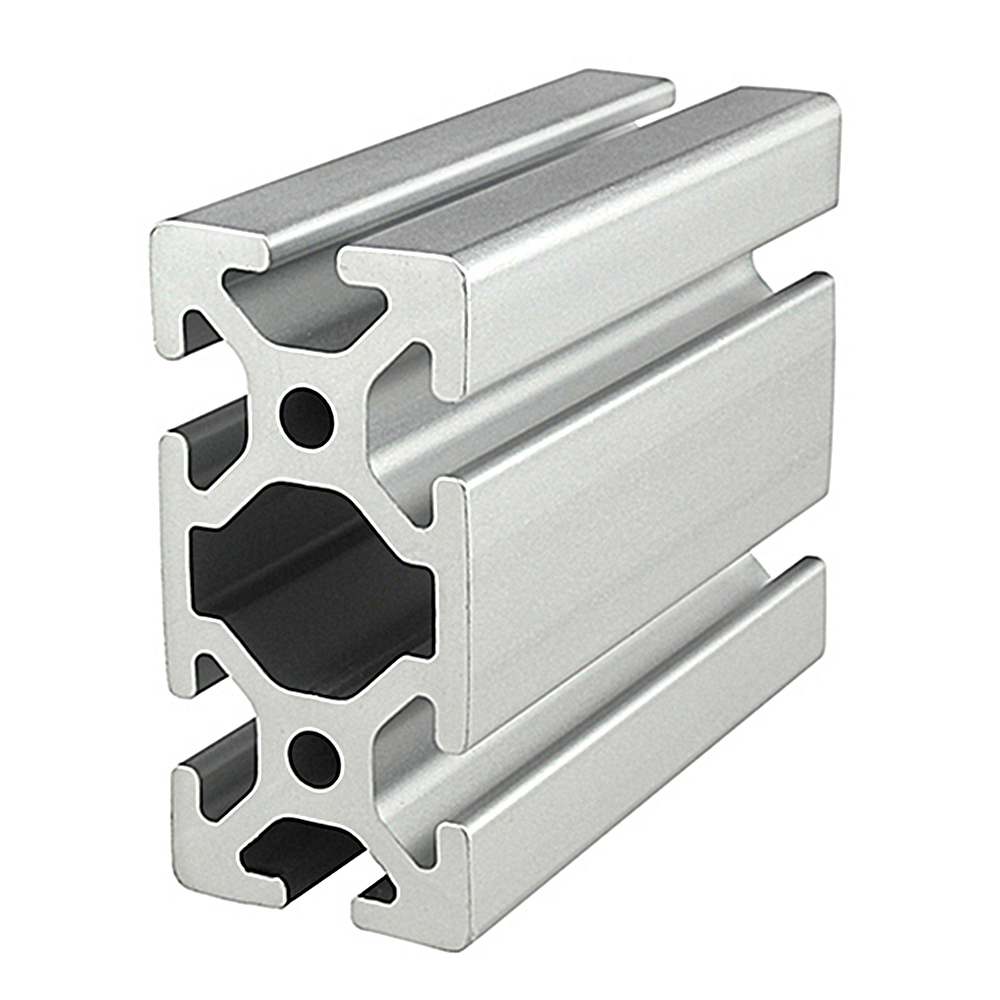

T Slot Aluminum Track

Many of the woodworking jigs and fixtures I make have at least one length of t-track built into them.

A t-slot aluminum extrusion provides an easy way to make jigs usable for different size workpieces as well as adding an adjustable clamping point for jig accessories such as stop blocks and toggle clamps.

This 1/4' t-slot track has a groove down the middle to keep the drill bit from wandering off center when drilling mounting holes.

Aluminum Extruded T Slot Track

A t-slot extrusion can be used in other places besides jigs. Use a pair on a router table to make an adjustable fence. Or use one on the fence to hold a featherboard or two.

Use them whenever you need to clamp anything anywhere along a straight line.

This flush-mounted T-Slot Track is 3/8' deep x 3/4' wide. T-Slot Tracks are available in three lengths and are designed to be mounted flush to the work surface. This keeps the work surface clear of obstructions when not in use. Great for workbenches, bandsaws, hold down jigs, drill presses and table saws. T Track, Knobs and Accessories Producing your own jigs or workshop accessories can vastly improve the quality of your output as well as speed up repetitive processes. The important thing is to start with quality fittings and Baladonia T-Track Hardware can be relied on to do the job time and time again.

The two most common t-slot sizes are 1/4' and 5/16'. These two sizes will cover most every woodworking application. In fact, I use 1/4' most of the time because it's cheaper and plenty strong for what I use it for.

These t nuts and t bolts make it easy to attach clamps and other accessories to the t-track.

It is best to use t-nuts and t-bolts when attaching accessories to the track. Regular nuts and bolts can wreck the slot if overtightened.

If you have to use a regular hex bolt, use a small washer to prevent the head of the bolt from digging into the soft aluminum.

I like to get my t-bolts extra long and cut them down to the length needed for each application. This way I only need to keep one length in each size on hand.

Mounting the t track

No matter what your application, you'll have to cut a dado with either a table saw or router to mount the track flush with it's neighboring surface.

A 3/4' x 3/8' deep dado is cut to keep this t track level with the top of the workpiece. I cut this dado with the table saw.

T-slot Aluminum Track

The 1/4' track that I use requires a dado that is 3/8' deep and 3/4' wide. The 5/16' track needs a dado 7/16' deep by 7/8' wide. I think these are fairly standard sizes, but always measure first before cutting.

Some t-track comes with pre-drilled mounting holes, but the version I like to use requires you to drill your own holes. They do however, provide a small groove in the center to help keep the drill bit from wandering.

Drilling your own holes takes a little extra time, but allows me to place them where it's convenient or necessary. I found with the other stuff, I was drilling extra holes where I needed them anyway.

Where to buy

I live in a small city of 35,000 people with only two major building supply centers. Trying to find stuff like this is maddening, so for years I've been ordering hard to find items online.

I get a lot of my jig parts from Lee Valley here in Canada. Look under hardware -- Jig & Fixture Parts. They have a very nice selection of top quality goodies, even if they are a bit pricey.

With the Canadian dollar hanging pretty close with the US dollar these days, I find myself hopping across the virtual border more often when I find great deals online. Online stores like Amazon carry a large assortment of t-track and related hardware.

One of the advantages of living in a large city is selection and availability of products. For those of us that prefer to live in smaller centers, the internet has evened the playing field. We can often get things shipped to our door cheaply and quickly for the same price a guy in the city might pay for gas running around to collect the things he needs. No white knuckle driving or one finger salutes... I love it.

Related Articles

T Slot Aluminum Extrusion Track

Using t-track on a crosscut sled fence...

Using t-track on a sacrificial fence...

Table Saw Jigs

New! Comments

Have your say about what you just read! Leave me a comment in the box below.'TSI has shown great support with our projects by making recommendations on a given design to make it working and cost-effective. They are very responsive when we ask questions and always willing to support whatever needs we may have in a very timely manner. Thank you.'

Teddy Kimn

Mechanical Engineer

NSI-MI Technologies

Suwanee, GA

With 25+ years of specifying, designing, fabricating and assembling T-Slot projects, we have the experience and the know-how to produce an assembly or kit for you quickly, efficiently and cost-effectively.

As Georgia’s only stocking and machining center for T-Slot extrusion, we are able to provide local technical support and fast turnaround on orders. This means you will get competitive pricing and reduced freight and handling costs.

Local Inventory (Stone Mountain, Georgia)

Engineering & Design

Complete Machining Services

Assembly & Testing

Kitting & Packaging

Call our Inside Sales department today at (770) 879-3500 for a consultation or quote on your next machine frame, work station, fixture, enclosure or guard.

Perhaps you don’t have a specific project in mind -- you’re simply interested in learning how T-Slot aluminum extrusion can make your life easier. We welcome the opportunity to conduct an “Introduction to T-Slots” session at your facility. Schedule a date or call us at (770) 879-3500.

- No welding required, which means no heat stress or warping, no long delays waiting for the project to make it through the weld shop

- No painting or surface preparation

- High strength-to-weight ratio

- Aluminum is easy to machine

- Assembly is done with simple hand tools

- No expensive fabricating equipment is required

- Frames and assemblies built with T-Slot extrusion are easily adjusted, modified or re-configured to accommodate design changes

- T-Slot extrusion looks great and won’t rust

Kind Words from A Customer

“My experience with TSI Solutions was fantastic. The end result was better than I expected. You gave us a profile that didn’t have grooves in it so the outcome looks very professional. Our other vendor provided the grooves and it tends to trap dirt and debris. Next, you tapped the top holes for the table to be mounted on which is work I don’t have to do. Lastly, you even included the hardware to mount the two steel tables with so I don’t have to track that down. Overall, Matt Martin of TSI Solutions and the assembly team did an awesome job.”

Todd Leonard

Megadyne Belt Corporation

If you are new to T-slot aluminum extrusion and would like a hands-on demonstration of its benefits and applications, we would be happy to visit your facility or have you visit ours. Call us to schedule an appointment at 770-879-3500or you can e-mailus.

Sales / Support

1-800-342-4874 sales@tsisolutions.us

TSI Solutions

2220 Centre Park Court

Stone Mountain, GA 30087